Double-wheel milling of soil-cement mixing wall Quality inspection of construction process:

1,The quality inspection items in the wall construction process shall include: cement-soil mixing wall water-binder ratio, cement content, admixture dosage, cement slurry pumping volume, the proportion of stable liquid; The sinking and lifting speed of the milling mixer and the construction interval time; The bottom and top elevation, wall thickness, verticality, wall position deviation and lap length of cement soil mixing wall;Specification, welding quality, verticality, elevation and positioning of core components;Preparation and strength test of soil-cement test block.

2,Double-wheel milling of soil-cement mixing wall The water-binder ratio and cement content of the grout shall meet the requirements of the design and construction technology. The grout shall not be isolated and shall comply with the following provisions:

(1)The quantity of inspection shall be determined according to each shift, and each shift shall not be less than3Times;

(2The grout water-binder ratio was tested by hydrometer, and the cement content was tested by measuring device.

3, cement slurry pumping quantity should be determined according to the design and construction process requirements according to a single wall, can be used to pump meter and pumping pressure to monitor and check the slurry pumping quantity.

4,The specific gravity of the stabilizer, the sinking and lifting speed of the mixer and the construction interval time shall comply with this code5Chapter of the relevant provisions and requirements.

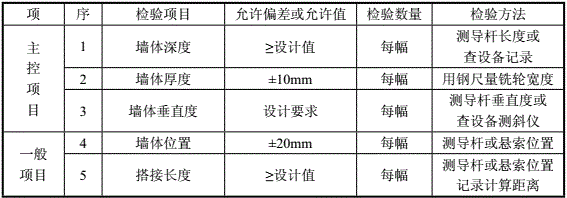

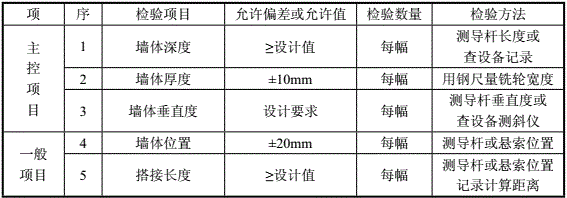

5During the construction period, the quality inspection standards such as the elevation of the bottom and top of the soil-cement mixing wall, wall thickness, wall verticality, wall position deviation and lashing length of the wall should conform to the provisions in the following table. The wall verticality should be monitored by the image data of the built-in inclinometer of the construction equipment.

Milling type construction into the wall allowable deviation

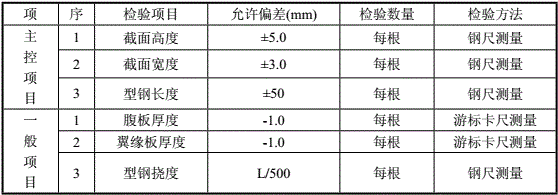

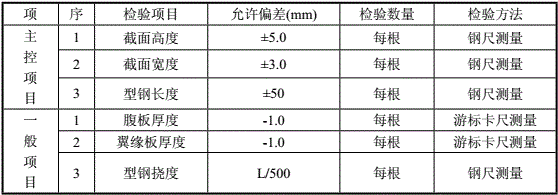

6,HThe specification of steel core material shall meet the design requirements, and the inspection method and allowable deviation shall conform to the following tableRules. The weld quality shall meet the design requirements and the current national standard WeldingHSteel"GB/T33814And Code for Welding of Steel StructuresGB50661The provisions of the.

HSection steel allowable deviation

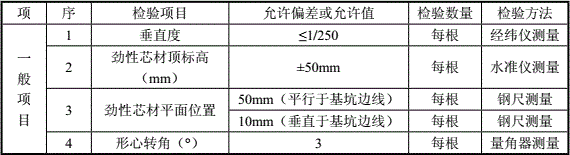

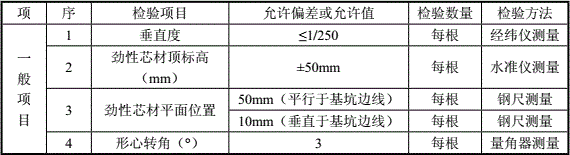

7,HThe vertical degree, elevation and allowable deviation of the steel core material shall conform to the following table

HType A steel core insert allowable deviation

Shanghai Qiangqiang Foundation Engineering Co., LTD. 's business covers foundation pit engineering, pile foundation engineering, land and waterFoundation treatment , slope treatment and other engineering fields. around"Excellent technology, reliable process, fast construction" technical requirements, is to provide customers with land, water foundation engineering technical consultation, construction services and other comprehensive solutions of the entity enterprise. Contact Number:400-1002850