SMWThe method of pile(Cement-soil mixing pile) Main construction steps are as follows:

First, construction preparation

Pile stirring machine in place, leveling pile machine, straightening pile frame (or drill tool).

Two, mixing pile construction:

1Grouting, stirring and sinking to the design pile bottom elevation;

2, grouting, stirring to the design pile top elevation;

3And repeat the above construction steps to complete the construction of all cement-soil mixing piles.

The construction technology of shotcrete sinking and shotcrete lifting is usually required to carry out a cycle of sinking and lifting. It is necessary to ensure that the whole pile length and whole process of shotcrete in the cycle process of sinking and lifting.

Three,SMWmethodinsertHsteel

insertHThe construction steps and requirements of section steel are as follows:

1, insert steel shall be usedQ235BGrade of steel andQ345BGrade steel, specifications, models and related requirements should be in accordance with "hot rolling.HSection steel and sectionsTSteel"GB/T 11263and The welding HSteel"YB3301To choose. forØ650@450Three - axis mixing pile, insert steel can be usedH500×300Specifications; forØ850@600Three - axis mixing pile, insert steel can be usedH700×300Specifications; forØ1000@750Three - axis mixing pile, insert steel can be usedH800×300Specifications.

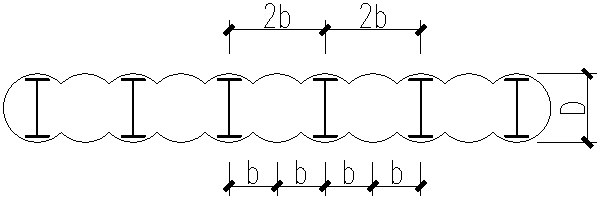

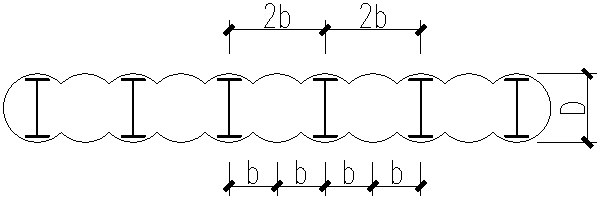

2The layout form of section steel should be determined according to the calculation. Several commonly used layout forms, including close plug type, plug two hop type 1 and plug one hop type 1, the schematic diagram is as follows (wherebIs the spacing between the centers of adjacent mixing piles,DDesign diameter for stirring pile) :

(a) type plug

(b) Insert two hop one type

(c) Insert one hop one type

figure1 Insert steel arrangement

3Before using antifriction agent, we should be familiar with the nature of the product and application instructions.

4When the surface of the steel is wet or dirty, it will affect the adhesion of the antifriction agent on the surface of the steel, resulting in the fall off when the steel is inserted. Therefore, before brushing antifriction agent, should remove the dirt and rust on the surface of the steel, and do dry treatment on the surface of the steel. After the inspection and approval of the supervision engineer, the section steel can be coated with anti-friction agent.

5In order to avoid large residual stress in section steel, proper welding sequence should be paid attention to when welding joints.

6When the section steel is inclined in the process of sinking due to the long section steel or the uneven soil layer, special attention should be paid to ensure the perpendicularity of the section steel in the two directions perpendicular to each other to ensure that the inserted section steel is perpendicular.

7If the water-cement ratio is properly mastered, the section steel can be inserted smoothly depending on its weight. If the insertion resistance is large, you can increase the number of mixing, adjust the cement slurry water cement ratio or other measures to reduce the sinking resistance. When the section steel cannot be inserted by its own weight, certain auxiliary measures can be taken, including the use of static force to insert the section steel, or the use of vibration hammer with hydraulic pliers vibration insertion, etc. The vibration hammer sinking process shall not affect the surrounding environment. Should avoid the use of free fall type down insertion mode, this way is not only difficult to ensure the correct position of the section steel, but also easy to deflection, perpendicularity is not easy to ensure, and easy to lead to safety accidents.

Four, drawHsteel

SMWmethodThe pileHThe construction steps of section steel pullout and recovery are as follows:

1, the surface of the steel waist beam limit or support anti-slip components, welding scar and so on clean is to make the steel can pull out smoothly.

2, steel protective materials should be used linoleum, plastic textile cloth or non-woven cloth, the thickness of the material should not be greater than5mm.

3And the grouting cement is adoptedP.O 42.5Ordinary Portland cement, slurry ratio is recommended1:1.15.

Shanghai Qiangqiang Foundation Engineering Co., LTD. 's business covers foundation pit engineering, pile foundation engineering, land and waterFoundation treatment, slope treatment and other engineering fields. Around" Excellent technology, reliable process", construction fast "technical requirements,Is to provide customers with land, water foundation engineering technical consultation, construction services and other comprehensive solutions of the entity enterprise.Contact Number: 400-100-2850