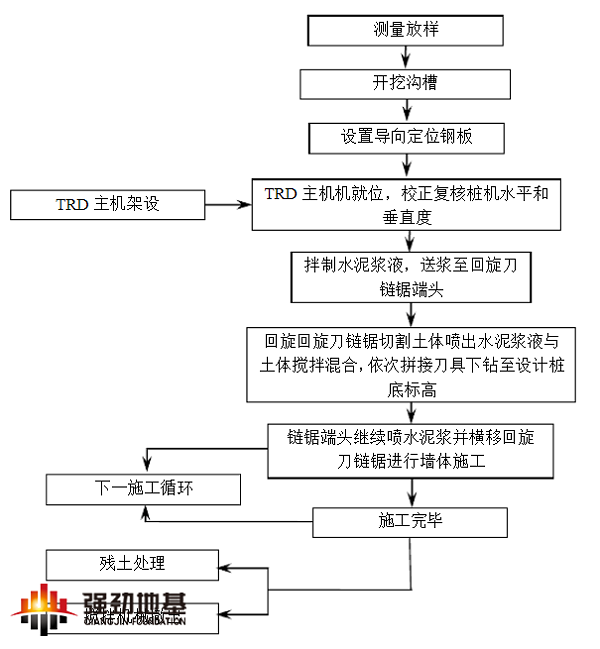

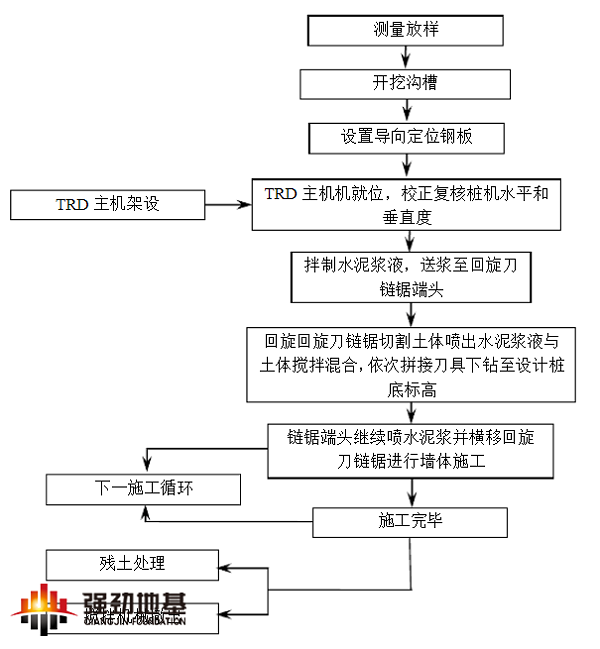

TRDThe method of pileThe construction process takes the chainsaw cutter as the main machine and tool, which is connected with the main machine in the process of inserting into the foundation. The rotary chainsaw can be moved vertically or horizontally to cut the underground soil, and cement is used as the hardener at the same time. In the construction site, the soil is cut according to the design depth and the design width of the wall protection. When the cement slurry hardener is injected into the soil at the end of the tool, high-pressure air is injected into the soil to fully mix the cement slurry and the soil in situ, and the soil in situ is consolidated by stirring, so as to form a continuous wall of equal thickness underground. The cement soil is then inserted at the designed spacing before hardeningHSteel is used as stress strengthening material. After the cement soil is hardened, a steel reinforced soil composite retaining wall with certain stiffness and strength is formed or only water is stopped. Then, retaining piles are constructed inside the cement soil wall for lateral pressure support, and steel pipe or concrete beam is used to support the inside of the foundation pit to form an overall foundation pit supporting system.

One, measurement lofting

According to the coordinate base point, release the pile position according to the design drawing, and set up temporary control pile, fill in the technical review form, submit acceptance.

Two, the trench excavation, the implementation of guide steel plate

The guide groove plays the role of positioning and guiding, and the control of vertical deviation of construction pile is particularly critical. The vertical deviation in construction is controlled in5‰Or less. In order to ensure that the mixing pile and section steel can be accurately positioned, the construction, first make guide wall, and thenTRDPile construction. In the process of guide wall trench excavation, according to the control line of the inner edge of the foundation pit enclosure, excavators are used to excavate, and underground obstacles are removed, and the residual soil of trench excavation is disposed of in time.

Three, rig positioning and drilling

TRDThe method of pileThe construction sequence is reciprocated from one end to the other, and the length of each cycle is20m, reciprocating three times into piles, and closely hangingHShaped steel heartwood.

Four, mixing and grouting speed

TRDThe mixing pile should be injected with cement slurry in the process of transverse movement, and the corresponding moving speed of the pile machine should be matched according to the grouting speed.

Section steel production and installation

Insert the mixing pile immediately after constructionHSteel. Use a crane to liftHSection steel, by section steel self weight insertion, insertion guaranteeHPerpendicularity of section steel. The section steel is coated with friction reducing material(The average static friction resistance per unit area is0.O4MPa)To reduce drag and ensure complete recovery. Section steel to be straight, smooth, no bending, no distortion. Set the directional device at the orifice. When the section is inserted to the design elevation, it is in use18The steel bar holds the section in place. The overflow of cement soil must be cleaned up, controlled to the design top elevation, and the next process of construction.

Six, pile crown beam

1,TRDStir the residual soil and floating slurry on the top of the pile wall and chisel the cement soil on the top of the pile and clean it with water;

2, according to the design requirements and construction requirements of the steel bar binding crown beam;

3The side mould adopts the combination steel formwork, and the support body adopts50mm×100mmThe wood and48mm Steel pipe;

4The section steel passing through the crown beam is wrapped by paper tire felt to isolate the section steel from the concrete. Facilitate the drawing and recovery of section steel;

Section steel removal and recovery

When the main body of the project is completed, the composite pile pulling machine will be used to pull out the steel inHIn order to ensure the smooth recovery of section steel, the drawing test and drawing test are carried out before the construction of section steel recovery. Due to the deformation of the enclosure structure leads to the deformation of the section steel, so that the section steel is difficult to pull out, the steel support should be applied according to the design requirements of pre-loading and the support force is uniform, in order to reduce the deformation of the enclosure structure, is to improveHAn effective method of section steel recovery.

Construction sequence: the pulling machine is in place, and the oil pressure reaction force is applied→Crane in place→liftingHsteel→Void grouting;

Shanghai Qiangqiang Foundation Engineering Co., LTD. 's business covers foundation pit engineering, pile foundation engineering, land and waterFoundation treatment , slope treatment and other engineering fields. Around"Excellent technology, reliable process ", construction fast "technical requirements, Is to provide customers with land, water foundation engineering technical consultation, construction services and other comprehensive solutions of the entity enterprise.Contact Number: 400-100-2850