With the continuous growth of our national economy, the scale of underground space development increases day by day. Traditional internal support can no longer be satisfiedFoundation pit engineeringDemand, especially environmental protection and other aspects of the requirements.

Traditional inner bracing mainly includes reinforced concrete bracing andConventional steel supportAnd so on. Reinforced concrete support in the process of construction and demolition will produce a lot of construction waste, not only cause serious adverse impact on the environment, but also cause a lot of waste of resources;Conventional steel supportIt belongs to statically determinate system, which has major safety risks and poor safety.

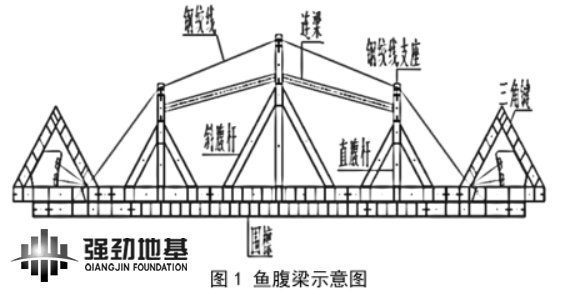

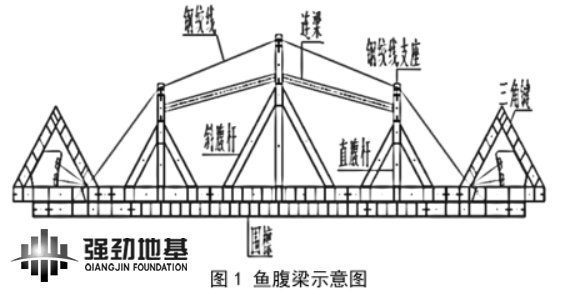

Prestressed prestressed steel support system Is made of fish belly beam (by high strength and low slack steel strand as a winding member,HSection steel as a stress beam, with different lengthsHSteel support beam, etc.), to support, Angle support, pressure beam, tie rod, triangle key, pressure device, column and other components of the force system.

Prestressed prestressed steel support technology is based on the principle of prestress. Prestress is applied through the tension of steel strand and transferred to the enclosing purlin through the straight belly rod and other rods, so as to reduce the deformation of enclosing purlin. It is equivalent to that the prestressed fish belly beam produces greater bending stiffness.

Characteristics of prestressed prestressed steel support system

Engineering safety: prestressed prestressed steel support system is high redundant statically indeterminate steel structure system; The failure form is ductile failure, which greatly improves the safety of the support system.

Construction convenience: The prestressed prestressed steel support system adopts standardized components, which are connected by bolts to facilitate the installation and removal of the support.

Environmental benefits: prestressed steel support system can ensure the safety of supporting structure and control the deformation of foundation pit by actively applying prestress, and greatly reduce the impact on the surrounding environment of buildings and pipelines. The components of the prestressed steel support system are standardized components. All steel components can be recycled and reused, which is in line with the national policy requirements of energy conservation and environmental protection.

Economic benefits: First of all, prefabricated prestressed steel support system through the fish belly beam and other components, can form a larger construction space, making the earth excavation and transportation and underground structure construction convenient and fast, so as to achieve the purpose of saving the construction period and reducing the project cost; Secondly, the standard components can be recycled and reused, which is also beneficial to reduce the project cost.

Shanghai Qiangqiang Foundation Engineering Co., LTD. 's business covers foundation pit engineering, pile foundation engineering, land and waterFoundation treatment, slope treatment and other engineering fields. around "Excellent technology, reliable process, fast construction" technical requirements, is to provide customers with land, water foundation engineering technical consultation, construction services and other comprehensive solutions of the entity enterprise. Contact Number:400-1002850