inCSM(Double-wheel milling of soil-cement mixing wall)In the construction method, the maximum power of conventional double-wheel milling is330kW, the maximum working pressure is300Bar, generally available atSoft soil layer, sand layer andConstruction in strong weathered rock.But they can't do anything about weathering rocks. If you haveaengineeringrequirementsCSMMust beInto the weathered rock, then can bear this heavy responsibility of the construction unitAnd construction equipmentThere must be very few.China Construction Second Bureau Three company innanjingBinjiang totalThe baseNo.2014G34projectDplotCSMThis is what happens in engineeringThe difficult problem.

figure1 Nanjing Binjiang headquarters base plan

Groundwater is rich, soil permeability is strong, water curtain needs to enter the strong weathering rock

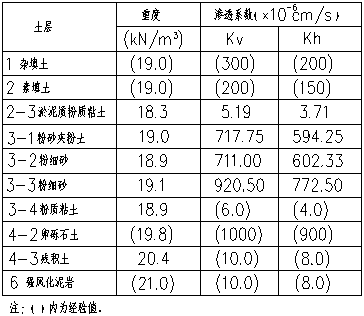

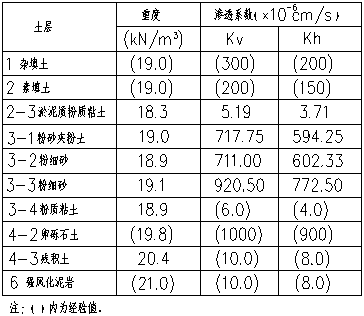

nanjingNo.2014G34projectDThe general contractor of the land parcel is the Third Company of China Construction Bureau II. The north side of the project is about the Yangtze River280m, groundwater is extremely abundant, put forward a very high requirement for the water stop of deep foundation pit excavation.thisThe excavation depth of the foundation pit is14.8~16.5m, with an area of about6600m2, and the soil layer within the excavation range is mainly sandy soil with extremely strong water permeability (see Table for the permeability coefficient of each soil layer1Shown below).

table1 Table of soil permeability coefficient

According to the designThe foundation pitWater stop curtain usedCSMMethod,Construction of the deepDegree of more than46m, and requires access to strongly weathered rock strata at least1mTo block the permeable layer.

Conventional double-wheel milling encounters moderately weathered rock strata, and the construction cannot continue

Conventional two-wheel milling was initially used for the project. The early construction is very smooth, after a distance of construction, in a water curtain distance pile bottom standardHigh return bad2mMilling head left and rightUnable to drill in.

It was later confirmed that there was a layer of medium-weathered rock below the strongly weathered rock, which was not detected in some areas during geological investigation due to the large fluctuation of the stratum.

Conventional twin-wheel milling could not drill to the designed depth, and construction was stalled. In order not to affect the construction period, the general contractor decided to construct the cast-in-place piles in other areas first.

Shanghai strong Yong to shoulder the heavy responsibility, reformed double wheel milling

During this period, the general contractor contacted Shanghai Qiangqiang Foundation Engineering Co., LTD. (hereinafter referred to as"Shanghai is strong").

After DETAILED UNDERSTANDING OF THE PROJECT AND on-site investigation, Shanghai QIANGJIN immediately organized the ENGINEERING DEPARTMENT, TECHNOLOGY DEPARTMENT and EQUIPMENT DEPARTMENT to carry out technical discussion, and then gave a positive reply to the general contractorShanghai is strong enough to complete the task.

Take over theAfter that, Shanghai Strong began to improve the dual-wheel milling according to the design scheme: the power pump station is adopted4Taiwan110kWMotor, tool head part cutting blade encryption and all equipped with special import alloy tool head for rock entry.

figure2 Milling cutter head

Special double wheel milling site performance is excellent, construction smoothly

When everything is ready, Shanghai strong special two-wheel milling approach construction. General contractor units, supervision units have come to the scene to watch. Under the public's gaze, milling head smoothly descended to the design elevation.

In the subsequent construction, the special two-wheel milling fully demonstrated its excellent performance.

Because the construction sequence is forced to be adjusted, the grouting pile constructed first has the phenomenon of diameter expansion in the silt layer"Big belly"). If it is conventional double-wheel milling construction, it is necessary to introduce special grinding equipment, grinding grouting pile first, and then construction of water stop curtain, which not only affects the construction period, but also increases the cost. However, this special double-wheel milling can easily grind off the "big belly" of the reamed cast-in-place pile while constructing the water stop curtain, so the construction period and cost are guaranteed.

figure3 Shanghai strong special double-wheel milling is under construction

At present, two-thirds of the project has been completed, and the overall construction of the foundation pit is proceeding as expected. The on-site performance and construction quality of Shanghai's strong operators have been praised by the general contractor and the owner.

Shanghai Qiangqiang Foundation Engineering Co., LTD. 's business covers foundation pit engineering, pile foundation engineering, land and waterFoundation treatment , slope treatment and other engineering fields. Around" Excellent technology, reliable process ", construction fast "technical requirements, Is to provide customers with land, water foundation engineering technical consultation, construction services and other comprehensive solutions of the entity enterprise. Contact Number:400-100-2850