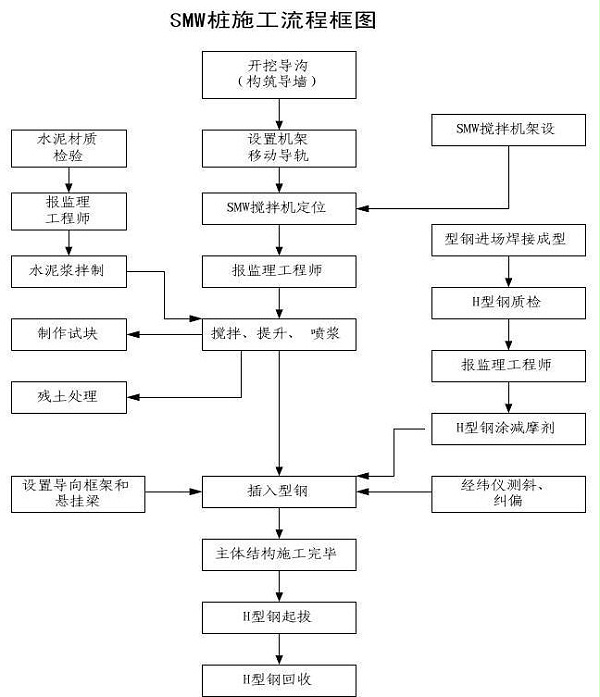

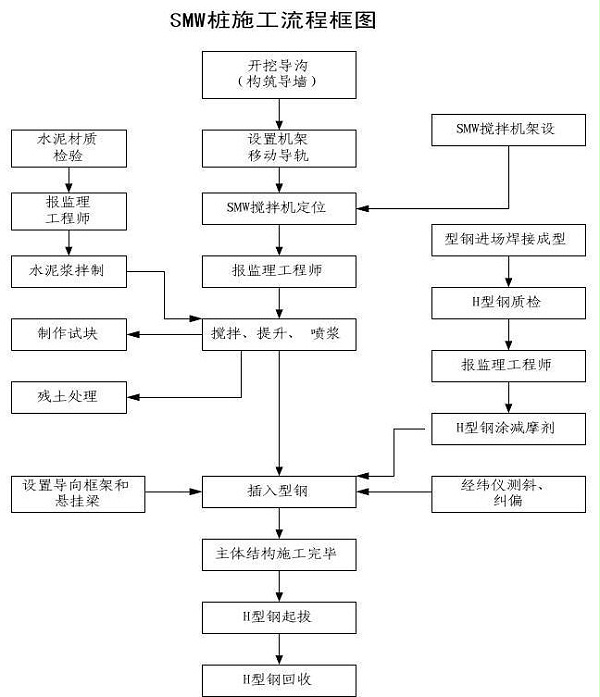

A,SMWmethodFlow chart of construction

Second, SMWmethodThe construction of the

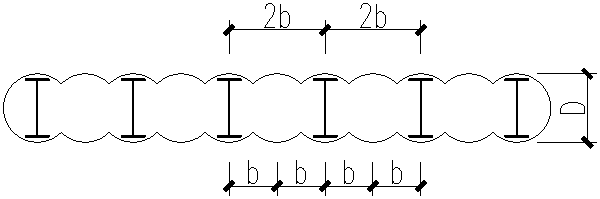

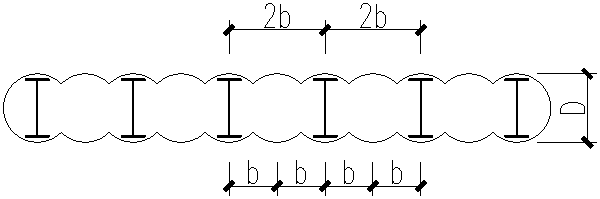

1And the way the section steel is inserted

(a) type plug

(b) Insert two hop one type

(c) Insert one hop one type

2,SMWmethodBasic requirements for section steel materials:

(1The raw materials, specifications and models of section steel shall comply with the design plan.

(2) section length on the basis of construction engineering design, while making the length can not meet the provisions of the design should be joining together beforehand, joining together to weld, if necessary can be made in the middle of the connecting head bidirectional body tenon to improve the stiffness of joint, welding surface with steel is consistent with the original plane, to ensure that the steel plug well.

(3The whole steel section must be flat and vertical, and the total bending cannot exceed1%And do not over15mm .

(4) each steel joint is not over2, and is not in the flexural, shear large part, the weld should meet the second level requirements.

(5) The outer surface of the steel should be smooth and smooth, remove the welding scar, and carefully brush with anti-wear agent.

Three,SMWmethodInserted steel

1, inserted steel should be immediately after the end of the mixing of soil-cement mixing pile.

2, the positioning clamping mold needs to be installed before the section steel insertion, to ensure that the midpoint of the positioning clamping mold is consistent with the midpoint of the cement-soil mixing pile, and the double verification method should be used when rechecking the position of the positioning clamping mold (Both the inserted steel spacing and the distance to distant points should be approved).

3The dead weight sinking method is generally used for the inserted steel, that is, the top of the section steel is lifted by the crane, so that the section steel is vertical, and the clamping mold is aligned and positioned, and then the rope is relaxed to make the section steel steady and uniform sinking to the design elevation. When the dead weight of the section steel tends to sink again, anti-slip measures are set at the top of the soil-cement mixing pile. When the dead weight of section steel can not reach the design elevation, mechanical equipment can be used to pressurize Sink it to the design elevation.

4The vertical degree of section steel sinking should be strictly guaranteed. The vertical hammer hanging by drilling rig and weft meter can be used to measure To ensure that the verticality error is not specified.

Four, Pull out of section steel

SMWmethodSection steel removal requirements:

1Section steel lifting should be carried out after the completion of foundation pit construction.

2, sections should be by the root, pull litres to use reinforced concrete roof beam around to do before pulling force platform, the first use of hydraulic jack to rose, pull steel after being steel loose gradually rise, pull to rise to a certain height and then pull up at a constant speed with lifting equipment, pull up the entire process to maintain steel vertical pull, to reduce the friction resistance and maintain section deformation.

3The empty holes in the cement-soil mixing pile body after the section steel is pulled out should be carefully backfilled with sandy soil immediately and compacted by shock when necessary.

Shanghai Qiangqiang Foundation Engineering Co., LTD. 's business covers foundation pit engineering, pile foundation engineering, land and waterFoundation treatment, slope treatment and other engineering fields. Around" Excellent technology, reliable process", construction fast "technical requirements,Is to provide customers with land, water foundation engineering technical consultation, construction services and other comprehensive solutions of the entity enterprise.Contact Number: 400-100-2850