This project for the design, procurement and construction (EPC) general contracting project, located in wenzhou economic and technological development zone coastal area to include soft foundation processing (vacuum preloading, the prestressed pipe pile and cement mixing pile, etc.), foundation pit supporting (SMW pile, steel sheet pile, etc.), underground pipe gallery (3.7 km), roads, Bridges, etc., The total cost of the project is about 1.15 billion yuan and the construction period is 1,095 days.

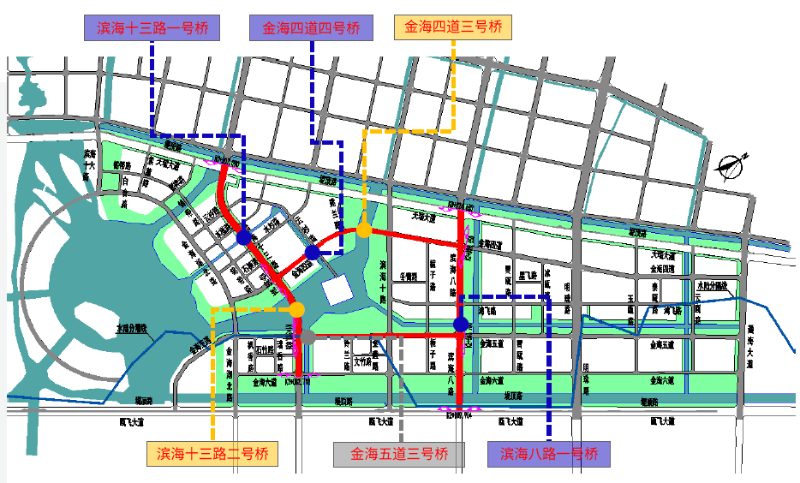

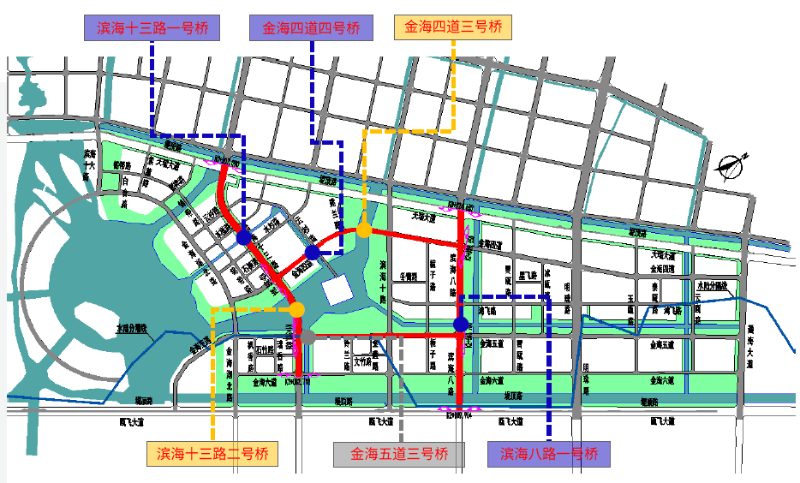

This project is designed, procured and constructed (EPCThe general contracting project is located in Binhai Core Area of Wenzhou Economic and Technological Development Zone, including Binhai Road 13, Binhai Road 8, Jinhai Road 4 and Jinhai Road 54The municipalRoads and6bridge.Total road mileage approx6.2 km, road width36/50m, the main engineering contents include soft foundation treatment (vacuum preloading, prestressed pipe pile, cement mixing pile, etc.), foundation pit support (SMWConstruction pile, steel sheet pile, etc.), underground comprehensive pipe corridor (3.7km), roads, Bridges, etc., the total cost of the project is approx11.5One hundred million yuan, construction period1095Days.

Aerial view of the project

Schematic diagram of municipal roads and Bridges in this project (bold red line in the figure)

ChangDao this project by the Beijing municipal engineering group co., LTD, Shanghai municipal engineering design & research institute (group) co., LTD., won the bid, Beijing ChangDao as a consortium led by fang, a Beijing ChangDao strong division (construction main body for a strong foundation in Shanghai engineering co., LTD.) this project construction and management.

Key point one: soft base processing-- The soil moisture content is high, the area is large, and the construction period is tight

The project is below the surface30mThe area is basically silt soil, which has the characteristics of fluidic shape, high moisture content, high compressibility and high sensitivity. Building roads and Bridges on this stratum poses great challenges to the bearing capacity and settlement of the foundation. The comprehensive pipe corridor and a variety of directly buried pipelines under the municipal road of the project are very sensitive to the foundation deformation, and have high requirements for the foundation settlement and differential settlement at the abutment. Therefore, it is necessary to conduct foundation treatment to eliminate the post-construction settlement of the project in advance, and improve the foundation bearing capacity to meet the use requirements. Therefore, the design and construction quality of soft foundation treatment is one of the key points of this project.

According to the design requirements, the area near the abutment is treated with prestressed pipe pile. The remote abutment area is treated by cement-soil mixing pile. For the rest of the road section"Plastic drain board+Vacuum combined load preloading "treatment for the above soft baseTo deal withThe totalArea of about35wanm2.

The project plane span is large, the road is longitudinal long, the reinforcement width is narrow, and the construction period is tight (the soft foundation processing period is one year), which poses a great challenge to the construction organization and arrangement. In order to save time effectively, vacuum preloading process is adoptedFDPRapid vacuum preloading technology, its main advantages are:

1, cancel the sand cushion layer under the traditional process, and the drainage board is directly connected with the vacuum filter pipe, which can realize the direct transfer of vacuum degree, change the mode of indirect transfer of vacuum degree through the sand cushion layer, reduce the loss of vacuum degree, help to improve the vacuum preloading treatment effect, but also shorten the construction period.

Direct connection between drain plates photo

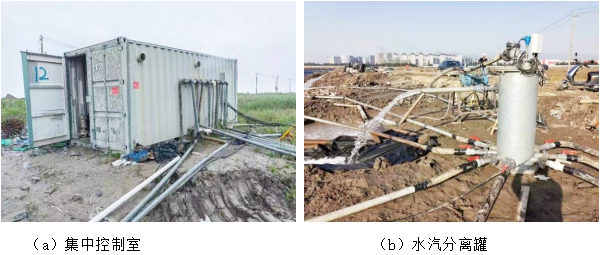

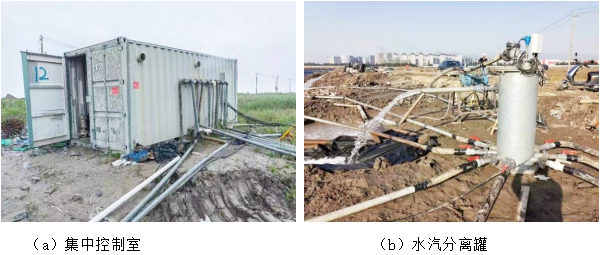

2,Using gas-liquid separation technology, average per3~4wan㎡fieldA centralized control room (high-energy vacuum pump) and a number of gas-liquid separation tanks are arranged in the ground. The construction efficiency is high, and the vacuum effect is good, which changes every800~1000㎡The traditional technique of arranging a jet pump.

The project is in2021years10The construction started in September, and the soft foundation treatment project is under construction. The construction progress of this project has exceeded80%, meet the requirements.

FDPPhoto of vacuum preloading equipment

Construction photo of plate planter

Photo of vacuum film after laying

Key two: comprehensive pipe corridor foundation pit support -- deep foundation pit, thick soft soil, great danger

Another important and difficult point of this project is the deep foundation pit support of the comprehensive pipe corridor. Foundation pit supporting construction will be carried out after vacuum preloading soft foundation treatment. The maximum foundation pit depth of the pipe corridor is reached13mSurface layer,30mThey are all silty soil with high water content and low strength, and belong to the sub-project with greater risk over a certain scale. Foundation pit supporting scheme adoptedSMWConstruction method pile, steel sheet pile, steel concrete support, steel combination support and so onForm.

Innovation point: the innovation of foundation pit fertilizer trough backfilling material

One innovation of this foundation pit is the use ofGSFlow-solidified soil was used to backfill fertilizer trough with new material instead of coarse sand in traditional backfill.GSFluid-solidified soil can be directly used from excavated silt andGSThe solidified soil, which is stirred by curing agent and poured by special mixing equipment and perfusion equipment, not only improves the backfilling compactness, reduces the deformation in the later stage of foundation pit, but also reduces the cost. Compared with medium coarse sand (local price is high), it not only has greater compressive strength, smaller displacement, and lower cost.

At present, the pile foundation under the pipe corridor is under construction, and the construction of retaining pile for the foundation pit can be carried out after the construction is finished.

Shanghai Qiangqiang Foundation Engineering Co., Ltd. has completed more than 1,000 projects in the fields of housing construction, underground space, subway, railway, highway, bridge, tunnel, airport, sea reclamation, and so on. Hundreds of projects it has participated in have won the "Luban Award of China Construction Engineering" or the "Magnolia Award of Shanghai Construction Engineering". Contact Number: 400-100-2850