- Home

- About us

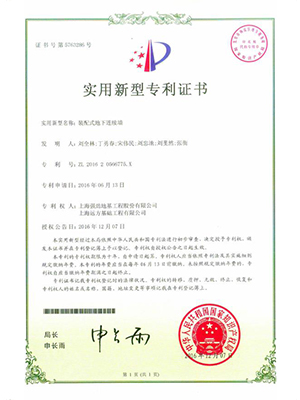

Company Profile The Company Culture Ecological Cooperation Partner Sustainable Development Company Qualification Company Honor Join Us Contact Us

- Foundation Engineering

Pile Foundation Engineering Foundation Pit Engineering Water Foundation Treatment Engineering Land Foundation Treatment Engineering

- Cases

Pile Foundation Engineering Foundation Pit Engineering Water Foundation Treatment Engineering Land Foundation Treatment Engineering Pile foundation + foundation pit + foundation engineering Projects Under Construction

- Technology

- Equipment

- News

Company news I at the scene The home of employees Love public welfare Encyclopedia