Shanghai Strong Foundation has a number of CSM construction equipment, with a large number of engineering construction experience, dual-wheel milling can be used to enter the weathered rock formation construction, the following content is the Shanghai strong foundation CSM construction method steel insertion process and requirements:

Shanghai strong foundation has a number of unitsCSMConstruction equipment, with a large number of engineering construction experience, double-wheel milling can be used in weathering rock construction, the following content for Shanghai strong foundationCSMConstruction process and requirements of section steel insertion:

After the construction of the mixing pile is completed, the crane should be immediately in place and ready for liftingHSteel.

HSection steel before use, at the distance from its top25cmOpen a center round hole, aperture about8cmAnd weld two thicknesses on both sides of the section steel1cmOf the reinforcement plate, whose specifications are450mm×450mm, the center opening is aligned with the upper hole of the section steel.

According to the elevation control points provided by the general contractor, the level is used to lead to the positioning steel, according to the positioning steel andHThe height difference of the top elevation of the section steel can be welded to the outside of the two webs of the section steel (φ12Wire), error control:

1,in±5cmwithin,The section steel inserted into the soil-cement part shall be uniformly coated with anti-friction agent.

2,Install the spreader and fixing hook, and then use50Ton crane liftingHSection steel, check its perpendicularity with line hammer.

3,It is arranged on the groove positioning section steelHSection steel positioning card, fixed into the section steel plane position, section steel positioning card must be firm, horizontal, and thenHThe bottom center of the section steel is vertically inserted into the body of the cement soil mixing pile along with the positioning card, and the perpendicularity is controlled by line hammer.

4,HAfter the section steel is inserted to the design depth, the channel steel is used to pass through the hanging bar and put on the positioning section steel. After the cement and soil mixing pile reaches a certain hardening time, the hanging bar and groove positioning section steel are removed.

5,ifHWhen the section bar cannot reach the designed elevation, the lower BAR can be repeatedly lifted to reach the designed elevation, and the line hammer is always used to track and control this processHPerpendicularity of section steel.

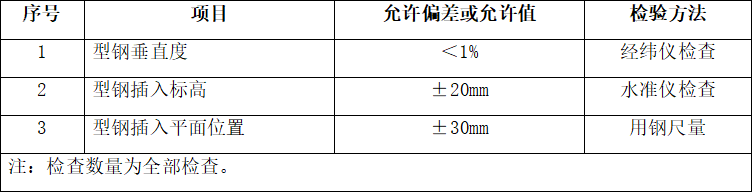

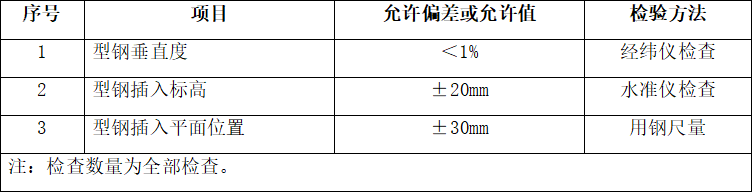

6The section steel should be inserted on the side near the foundation pit. The inspection standards of the insertion length, perpendicularity deviation, section steel elevation and insertion plane position are shown in the following table.

Shanghai Qiangqiang Foundation Engineering Co., LTD. 's business covers foundation pit engineering, pile foundation engineering, land and waterFoundation treatment , slope treatment and other engineering fields. Around"Excellent technology, reliable process", construction fast "technical requirements, Is to provide customers with land, water foundation engineering technical consultation, construction services and other comprehensive solutions of the entity enterprise. Contact Number:400-1002850