1) Hole wall collapse: hole wall collapse due to poor soil quality of pile position or groundwater seepage. Before excavation, the site soil should be excavated in staggered pile positions, shorten the height of each section and observe the soil looseness at any time. If necessary, the slump hole can be blocked with brick, steel sheet pile and wood pile. The operation process should be compact, leaving no spacing and avoiding slump.

A,Long auger bored pilePrevention and control measures for common quality problems

1Hole wall collapse: hole wall collapse due to poor soil quality of pile position or groundwater seepage. Before excavation, the site soil should be excavated in staggered pile positions, shorten the height of each section and observe the soil looseness at any time. If necessary, the slump hole can be blocked with brick, steel sheet pile and wood pile. The operation process should be compact, leaving no spacing and avoiding slump.

2There are too many empty soil at the bottom of the hole: there are more empty soil and broken bricks after hole forming and trimming, and they are not carefully removed. Before and after the steel cage should carefully check the bottom of the hole, remove debris. Seal the back with cement mortar or concrete if necessary.

3Water at the bottom of the hole: water seeps quickly or rainwater flows into the local water, and drainage is not timely, water will appear. In the process of excavation, the bottom of the hole should be dug and pumped in time. If there is a small amount of water, pouring concrete can be used in the first half dry hard, a large amount of water and eliminate difficulties for a while, then the application of underwater pouring concrete method, to ensure the quality of construction.

4Distortion and deformation of steel cage: steel cage processing welding is not firm, not to take support to strengthen the steel bar, transport, lifting deformation, distortion. Reinforcement cage should be processed on a special platform, the main reinforcement and stirrup spot welding firm, support reinforcement measures to be reliable, lifting to vertical, so that it smoothly into the pile hole to keep the skeleton intact.

Second,Long auger bored pileCommon quality problems and preventive measures

1Blocking pipe,

Two drilling doors are designed on both sides of the auger bit. The doors are closed during the construction to prevent cuttings from entering the drill pipe and blocking the drill pipe. When pumping concrete, two drill doors are opened with the increase of pump pressure, and concrete is poured into the hole. Once the drilling door cannot be opened when lifting the drill, there will be no concrete in the drill hole directly, and the consequences will be serious. Therefore, it is required to check whether the drilling door is stuck before and after each drilling. If there is a viscous soil layer with high plasticity, the drilling tool rotary pump concrete method is used, which is to make the drilling tool in the positive rotation under the lifting and pulling of the concrete at the same time, so as to make the mud loose or fall off in the drilling door, so as to open the drilling door under the pump pressure.

2, sticking

In the process of drilling a long auger, if the drilling tool is lowered too fast, the cuttings drilled out of the hole too late to take out the hole and backlog between the drill pipe and the hole wall, it will cause stuck drilling accident when serious. If the accident is minor, the rotary power supply should be turned off immediately, and the drill tool should be lifted with the minimum lifting speed before re-drilling. If the accident is serious, first of all, the beam under the rig tower should be cushioned with machine sleepers, and then the minimum lifting speed should be used to pull the drill tool.

3, broken pile, reduced diameter and pile defects

The main reason for this problem is that the speed of drilling pipe lifting is too fast, and the amount of concrete pump does not match with it. In the process of drilling pipe lifting, negative pressure is generated in the drilling hole, so that the hole wall collapse caused by broken pile, and sometimes it will affect the adjacent pile. The first way to solve this problem is to choose a reasonable drilling pipe lifting speed, which is usually1.8~.4m/minTo ensure that the buried depth of drill in concrete is always controlled in1mAbove, ensure that with pressure lift drill; Second, jump pile, if the adjacent pile spacing is less than5dWhen, must jump across the pile.

4The pile head is not complete

The main reason for this problem is that the ash stop surface is too low, there is not enough waste pile head reserved, sometimes too fast lifting speed will also lead to low pile head, the solution is to ensure that the ground and effective pile top elevation distance is not less than when leveling the workshop0.6m, stop ash surface is not less than the effective top0.6m.

Three,Long auger bored pileEngineering quality assurance measures

1Guarantee Project:

(1The raw materials and concrete strength of the cast-in-place pile must meet the design requirements and construction specifications.

(2) The actual amount of concrete is strictly prohibited to be less than the calculated volume.

(3) The elevation of pile top and the treatment of floating slurry after pouring concrete must conform to the design requirements and construction specifications. In this project, the elevation of the completed surface required by pouring concrete is higher than the design elevation of pile top500MM.

(4) The hole formation depth must meet the design requirements of the bearing layer. The thickness of the sediment is strictly prohibited to be greater than that of the pile with the main end bearing100mm.

(5) after the concrete is perfused24h Inside,5m The adjacent piles within the scope shall not be drilled.

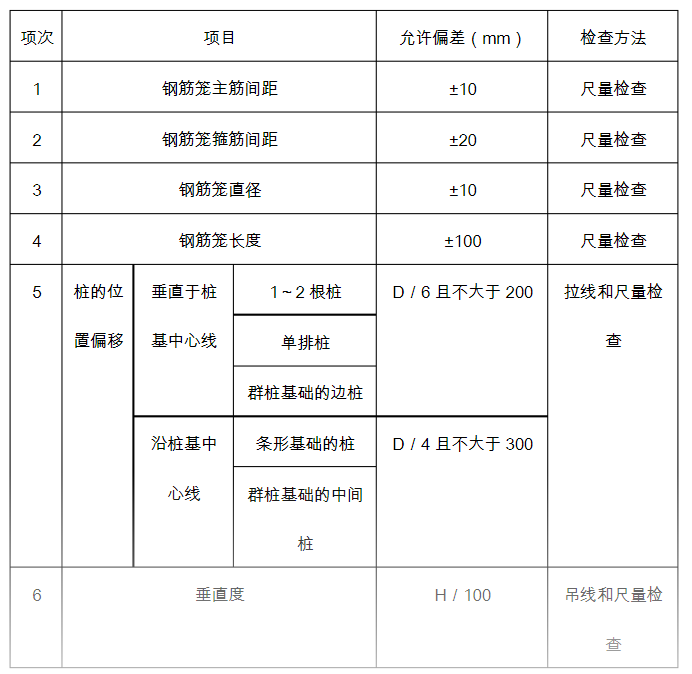

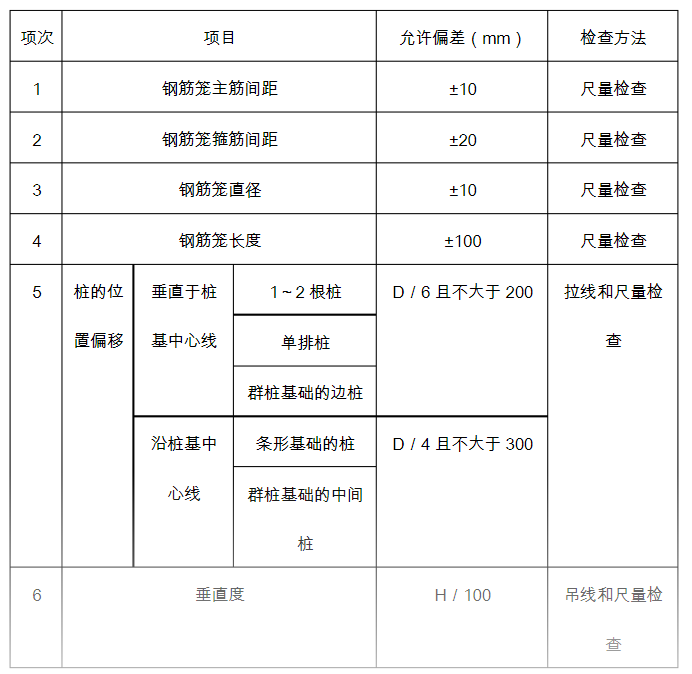

2. Allowable deviation items:

Shanghai Qiangqiang Foundation Engineering Co., LTD. 's business covers foundation pit engineering, pile foundation engineering, land and waterFoundation treatment, slope treatment and other engineering fields. Around" Excellent technology, reliable process", construction fast "technical requirements,Is to provide customers with land, water foundation engineering technical consultation, construction services and other comprehensive solutions of the entity enterprise.Contact Number: 400-100-2850