Foundation pit support is to adopt retaining, reinforcing and protecting measures for the side wall of foundation pit and surrounding environment to ensure the safety of the surrounding environment of foundation pit and the stability of soil, at the same time to ensure the construction of the underground structure of the building, to meet the requirements of basement construction with enough space. There are many forms of foundation pit support, each of which has its own advantages and disadvantages.

Foundation pit supporting By retaining, reinforcing and protecting the side wall of the foundation pit and the surrounding environment, the safety of the surrounding environment of the foundation pit and the stability of the soil are guaranteed, and the construction of the underground structure of the building is guaranteed, so as to meet the requirements of the basement construction with enough space. There are many forms of foundation pit support, each of which has its own advantages and disadvantages.

1. Slope foundation pit excavationFoundation pit supporting

Advantage: The regulation is smooth only, the price is the most cost-effective.

Disadvantages: high requirements for the surrounding environment of the site, and large fill back.

Applicable conditions: wide site, no key buildings around the project.

Second, deep mixing cement wallFoundation pit supporting

Deep mixing soil-cement parapet wall is mixed with cement mortar by deep mixing machine,A cylindrical cement retaining wall formed by overlapping with each other.

advantages:Because of the general pit support,Is conducive to the rapid excavation of earth machinery; It has the dual role of retaining soil and waterproof; Under general conditions more economic; Construction without vibration, no noise, less environmental pollution, mild compaction.

Disadvantages: displacement, thickness is relatively large, for large length of the foundation pit, It is necessary to take measures such as middle pier and arch to limit the excessive displacement;Special care should be taken during construction to avoid affecting the surrounding environment.

Applicable conditions: bustling area project.

Three, high pressure rotary jet grouting pileFoundation pit supporting

The common raw material of high-pressure rotary jet grouting pile is cement mortar,It is the use of high pressure rotating nozzle to spray cement mortar into the soil layer and sand mixed to produce cement soil reinforcement,Lap each other to form row pile,Used for retaining soil and waterproofing.

Advantages: Construction machinery and equipment compact structure, small size, high mobility, small footprint,And the vibration of the construction machine is small,Low noise,It is not easy to produce harm to the surrounding housing construction.

Disadvantages: A lot of mud discharge during construction,Easy to cause environmental pollution. For the stratum where the groundwater flow is too rapid, Permafrost and soil with severe corrosion to cement in karst area without filling,Because the gushing slurry cannot condense around the grouting pipe,Are not suitable for this method.

Applicable conditions: small construction space of the project.

Four, channel steel sheet pileFoundation pit supporting

It is a simple steel sheet pile parapet,By bad steel front and back buckle lap or side by side. Bad steel long6~8meter ,The model is determined by calculation.

advantages: Good durability,High secondary utilization rate; Construction is convenient,Short time limit.

Disadvantages: can not block water and soil in the fine particles, Water isolation or precipitation measures should be taken in areas with high water table; The bending resistance is weak and the supporting stiffness is small,The deformation is large after excavation.

Applicable conditions: mostly used for deep layer≤4mA shallow foundation pit or trench.

Five, bored pileFoundation pit supporting

drillingThe cast-in-place pile has the characteristics of high bearing capacity and small settlement. In the construction of punching cast-in-place pile, there are two kinds of mud wall forming method and whole casing construction method because of the different wall forming.

advantages:Construction without vibration, no noise and other effects,There is no compaction,Little impact on the surrounding environment; High wall strength,Stiffness big,Good support stability,Little deformation; When the engineering pile is also cast-in-place pile,Can be synchronized construction,Thus the construction is conducive to the construction organization, short construction period.

Disadvantages: the gap between piles is easy to cause soil erosion,Especially in the high water mark soft clay area, According to the engineering conditions, grouting, cement mixing pile, rotary jet grouting pile and other construction measures should be taken to solve the water retaining problem.

Applicable conditions: row pile type in the most used one,Often used in deep pits7~15m Foundation pit engineering support, Suitable for soft clay and sandy soil areas.

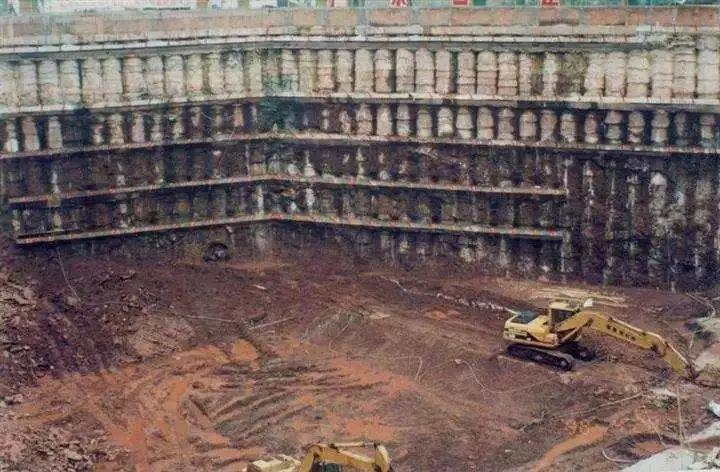

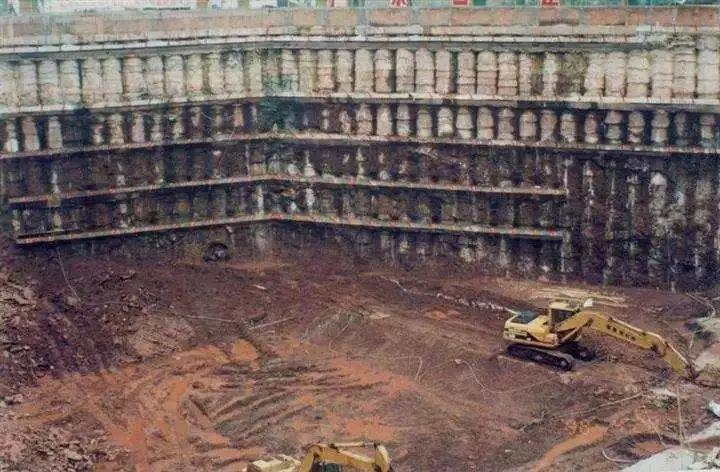

6. Underground diaphragm wallFoundation pit supporting

Advantages: high bending stiffness, good water stop effect, is a strong support structure in the form of support.

Disadvantages: High project cost, construction needs professional equipment.

Applicable conditions: poor and complex geological conditions, large depth of foundation pit, high environmental requirements of the surrounding foundation pit.

Seven, soil nail wallFoundation pit supporting

Soil nailing wall is a kind of slope stable foundation pit support, and its active embedment,Increase slope stability,Keep the slope stable after excavation of foundation pit.

Advantages: stable and reliable, simple construction and short duration, good effect, good economy, should be actively promoted in areas with good soil quality.

Defect: THE AREA WITH BAD SOIL QUALITY IS USED DIFFICULT.

Application conditions: For good soil layer area.

Eight, SMWmethodFoundation pit supporting

SMWThe construction method is also called the stiffened cement - soil mixing pile method,That is, it is inserted into the cement soil pileHSteel etc.(Most of themHsteel, Also inserted tensile steel sheet pile, steel pipe and so on), Combine load bearing with seepage and water retaining,So that it has both force and impermeability function.

Advantage:1, has little influence on the surrounding environment, does not disturb the adjacent soil, and can effectively control the settlement of surrounding ground structures;

2, good impermeability, construction method pile machine continuous operation of the wall without joints, so that it is more reliable than the traditional continuous wall water stop;

3, the stiffness is large, the supporting effect is good;

4, simple structure, simple construction, short construction period;

5Because the section steel can be recycled and reused, the cost is lower.

disadvantages1There are still many problems that need to be further studied in the aspect of the cooperative work of stirring pile and section steel.

2There is no uniform standard for some design and construction parameters of steel cement soil mixing wall, and the construction quality is difficult to guarantee.

3Since the pores left in the stirred pile after the section steel removal need to be backfilled by grouting and other measures, especially when the adjacent deformation sensitive structures, the backfilling quality requirements are higher.

Applicable conditions: can be used in clay, sand, gravel soil, gravel soil and other soil layer.

eightFoundation pit supportingEach method has its own advantages and disadvantages. In the design of foundation pit support, the actual situation of the site should be fully considered, and the reasonable, safe, economic and environmental protection method should be chosen.

Shanghai Qiangqiang Foundation Engineering Co., LTD. 's business covers foundation pit engineering, pile foundation engineering, land and waterFoundation treatment, slope treatment and other engineering fields. Around" Excellent technology, reliable process", construction fast "technical requirements,Is to provide customers with land, water foundation engineering technical consultation, construction services and other comprehensive solutions of the entity enterprise.Contact Number: 400-100-2850