1. Surveying and laying out according to the coordinate reference (control) point provided by the owner (or the general contractor), carry out the setting out positioning and engineering survey according to the design drawing, and make the permanent point and temporary point marks. The survey technology review list shall be completed after setting out and line, and the next procedure shall be carried out after the general contractor and supervision unit check and pass.

Construction scheme of three - axis cement - soil mixing pile for Shanghai strong foundation

1, measuring the line

According TO THE COORDINATE REFERENCE (CONTROL) POINTS PROVIDED BY THE OWNER (or the general CONTRACTOR), carry OUT the LOFting and positioning and engineering survey according to the design drawing, and make the permanent point and temporary point marks. The survey technology review list shall be completed after setting out and line, and the next procedure shall be carried out after the general contractor and supervision unit check and pass.

2, excavate trench

According to the control line of the inner edge of the foundation pit enclosure, excavators should be used to excavate the trench and remove underground obstacles. The residual soil should be treated in time to ensure the normal construction of the three-axis mixing pile and meet the requirements of civilized construction site.

3, positioning line placement

Place positioning wires in the direction of parallel grooves, spaced approx8~20mwithФ16Rebar fixed positioning wire.

4And hole location of three-axis stirring pile

Ф650The three-axis center spacing of the three-axis stirring pile is900mmAccording to this size, the three-axis hole position is measured in the parallel positioning line.

5, pile machine in place

The pile machine shall be placed in place under the unified command of the shift monitor, and the steel plate shall be laid under the pile machine first, and then the subgrade box shall be laid on the top. Before moving, the situation of the upper, lower, left and right aspects shall be clearly seen, and any obstacles shall be cleared in time. After moving, the position shall be checked and corrected in time. The pile machine should be smooth and straight, and the theodolite or line hammer should be used to observe to ensure the vertical degree of the drill; The deviation of pile position of triaxial stirred pile should be less than20mm. After piling, the deviation of pile center shall not exceed50mm, the vertical deviation of pile body shall not exceed1/200.

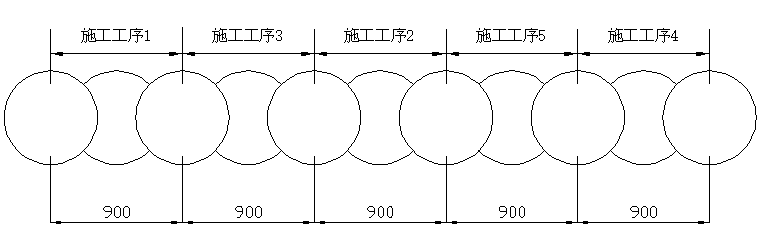

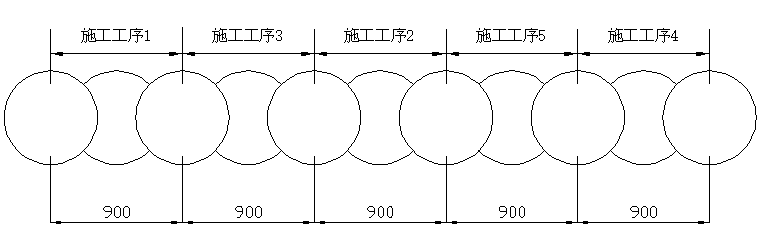

6, construction sequence

The construction of three-axis mixing pile is carried out in the following order, as shown in the figure:

7Preparation of cement slurry and slurry injection

(1The cement slurry mixing system (automatic mixing station) is set up at the construction site, and the cement tank is placed nearby, and the cement slurry is stirred according to the requirements before starting up. The prepared cement slurry is sent into the slurry bucket for use.

(2After the cement paste is prepared, the stagnation time shall not exceed2Hour, the construction interval of adjacent mixing piles in lap construction shall not exceed12Hour (initial setting time).

8, drilling and stirring

The three-axis mixing pile body adopts the construction technology of two spraying and two stirring. The cement and undisturbed soil must be stirred evenly. Grouting is used in the process of sinking and lifting, and the sinking and lifting speed is strictly controlled.

9, cleaning, displacement

Add a proper amount of water to the hopper, open the mortar pump, clean the grouting pipe and other equipment used, and then shift and carry out the construction of the next pile.

Shanghai Qiangqiang Foundation Engineering Co., LTD. 's business covers foundation pit engineering, pile foundation engineering, land and waterFoundation treatment , slope treatment and other engineering fields. Around"Excellent technology, reliable process ", construction fast "technical requirements, Is to provide customers with land, water foundation engineering technical consultation, construction services and other comprehensive solutions of the entity enterprise. Contact Number:400-1002850