Construction Technology of double wheel milling diaphragm wall under cement soil (  CSM construction method combines hydraulic milling machine and deep mixing technology. By mixing the soil and cement slurry in situ at the construction site, it can be used for seepage prevention wall, retaining wall, foundation reinforcement and other projects. Compared with other deep mixing technology, CSM construction method has higher adaptability to the stratum and can cut hard soil (gravel bottom, rock layer).

The construction of diaphragm wall by using traditional hydraulic milling machine has high construction cost and many supporting equipment, so it is only suitable for large-scale engineering projects.double Rotary milling deep mixing cement subsoil diaphragm wall Construction Technology (CSMMethod)Combined with hydraulic milling machine and deep mixing technology, by mixing the soil and cement slurry in situ on the construction site, it can be used for seepage prevention wall, retaining wall, foundation reinforcement and other projects, and the adaptability of the formation is higher than other deep mixing technology, can cut hard soil (gravel bottom, rock).

1, process characteristics

(1) The construction equipment is light and easy to operate: Crawler host, small footprint, flexible movement. When the milling wheel rotates deep into the stratum to cut and destroy the soil, the curing agent is injected. Forced stirring of loosened soil. It can not only be used as a single impermeable wall, but also can be inserted into the steel section to form a underground diaphragm wall integrating soil retaining and water stopping.

(2The construction technology is scientific and feasible: the hydraulic milling machine and deep mixing technology are adopted to mix the soil in situ and cement slurry on the construction site, which can be used in the seepage prevention wall, retaining wall, foundation reinforcement and other projects. Compared with other deep mixing processes, this process has higher adaptability to the formation and can cut hard formation.

(3) construction effect economic, environmental protection and energy saving: The technology is low noise, low vibration, can be close to the building construction, regular hole shape, high drilling efficiency; At the same time, the inserted section steel can be recycled and reused, saving steel resources; No pollution to the original soil and groundwater.

2, scope of application

This craft construction machine has two types of guide rod type and suspension type, guide rod typeDouble milling deep mixing equipmentCan be cut stirring depth45mThe suspension Double milling deep mixing equipmentCutting and stirring depth can be reached65m. Suitable for clay, sand, gravel soil and less than or equal to100MPaThe breeze of the rock formation. Low noise, low vibration, can be close to the building construction, especially for the small site, complex surrounding environment of foundation pit construction.

3, process principle

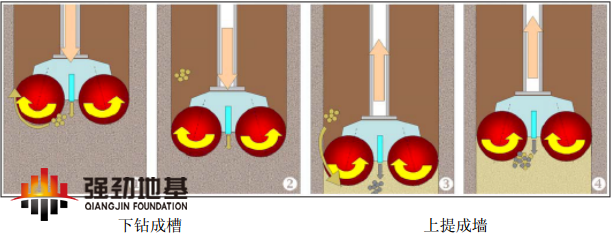

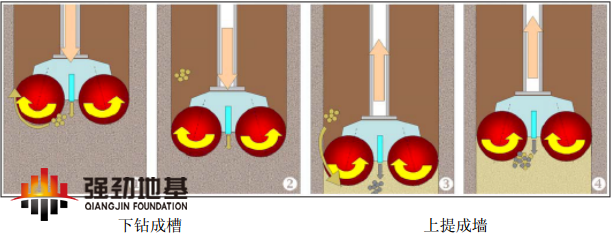

double Rotary milling deep mixing cement subsoil diaphragm wall Two groups of milling wheels are used to rotate and stir horizontally in axial direction to form the modified soil in rectangular groove section. The drill tool is equipped with two motor driven iron wheels in a waterproof gear box at the bottom of the drill tool and connected to the Kjelner drill pipe via a special frame or wire rope suspension. When the milling wheel rotates deep into the stratum to excavate and destroy the soil, the curing agent is injected to forcibly stir the loosened soil. It can not only be used as a single impermeable wall, and can be inserted into the steel, the formation of soil retaining and water stop in one of the wall. With appropriate internal support structure or external anchor structure, a safe and reliable foundation pit supporting system can be formed quickly. According to the condition of soil quality and groundwater, combined with appropriate precipitation measures, to ensure the safety of foundation pit supporting structure.

Shanghai Qiangqiang Foundation Engineering Co., LTD. 's business covers foundation pit engineering, pile foundation engineering, land and waterFoundation treatment , slope treatment and other engineering fields. around"Excellent technology, reliable process, fast construction" technical requirements, is to provide customers with land, water foundation engineering technical consultation, construction services and other comprehensive solutions of the entity enterprise. Contact Number:400-1002850