The INSPECTION ITEMS AND technical INDEXES of raw materials such as cement and admixture used in SMW construction slurry mixing should meet the design requirements and relevant national standards. Check quantity: Check by batch. Inspection method: Check product certificate and retest report.

1,SMWThe inspection items and technical indexes of raw materials such as cement and admixture used in construction slurry mixing should meet the design requirements and relevant national standards.

Check quantity: Check by batch.

Inspection method: Check product certificate and retest report.

2,SMWConstruction method of grout water cement ratio, cement content should meet the design and construction process requirements, grout segregation shall not be allowed.

Inspection quantity: according to the bench check, each bench should not be less than3Times.

Test method: grout water cement ratio application hydrometer spot check; Cement content should be checked by measuring device.

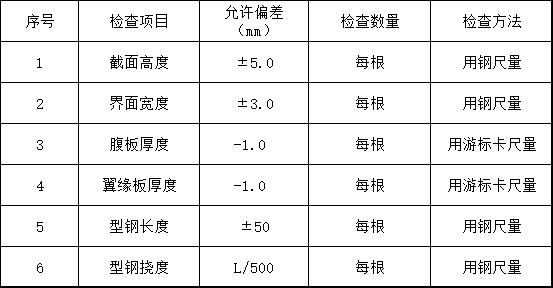

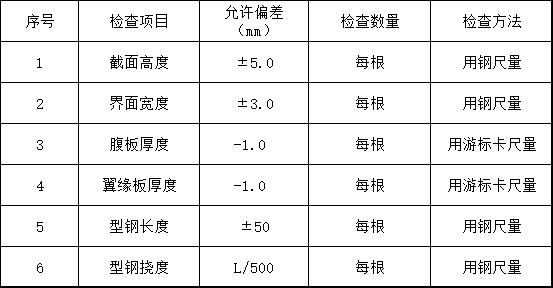

3, weldingHThe weld quality of section steel shall meet the design requirements and the current industry standard WeldingH"Section steel" and "Technical Regulations for Welding of Steel Structures in Construction".HThe allowable deviation of section steel shall conform to the following table.

SMWMethod of constructionHSection steel allowable deviation

4,SMWBefore the construction method, when the soil-cement strength data of similar soil properties are lacking or the requirements of soil-cement strength design need to be met by adjusting the amount of cement, water-cement ratio and the type and quantity of admixture, the indoor ratio test of soil-cement strength should be carried out to determine the soil-cement28dUnconfined compressive strength. The soil sample used in the test shall be taken from the soil layer within the depth range of the soil-cement mixing pile. When the soil layer characteristics are obvious and the soil properties are different, it is advisable to configure cement soil samples separately.

5Before foundation pit excavation, the strength of cement-soil mixing pile should be tested, and the strength index should meet the design requirements. The strength of cement-soil mixing pile should be determined by grout block strength test or by drilling pile core strength test. The test method of pile strength shall comply with the following provisions:

(1) The grout test block strength test shall take the grout of soil-cement mixing pile which has just been stirred and has not yet solidified to make the test block, and each shift shall sample check1Each pile should not be less than2Each sampling point shall be made3A block. The sampling point should be set above the bottom of the foundation pit1mRange and above the bottom of the pit at the weakest soil stirring pile. The test block should be sealed and cured under water in time28dThen the unconfined compressive strength test was carried out.

(2Geological drill and reliable core-taking drill shall be adopted for the strength test of pile core. After the construction of stirred pile, the stirred pile shall be drilled28dAged soil-cement core samples, drilled core samples should be immediately sealed and timely unconfined compressive strength test. The number of spot checks shall not be less than the total number of piles2%, and not less than3The root. The number of cores per pile should not be less than5group,Each group should not be less than3A block. Core samples should be selected from the pile cores drilled continuously in the whole range of pile length, and sampling points should be taken from different depths and different soil layers along the pile length5And a sampling point should be set near the bottom of the foundation pit. The strength of test block obtained by drilling pile core should be multiplied by the condition of core sample in the process of drilling pile core1.2~1.3The coefficient. The void after the completion of drilling and coring should be filled with grouting.

(3When the corresponding relationship between the in situ test results of static penetration, standard penetration or dynamic penetration and the strength test results of grout block or drilled pile core can be established, the in situ test can also be used to test the strength of pile body.

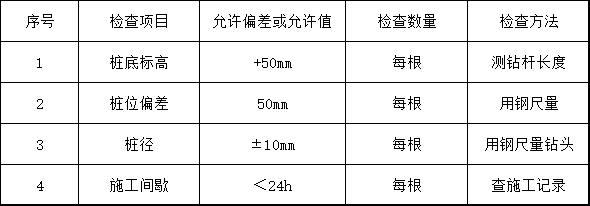

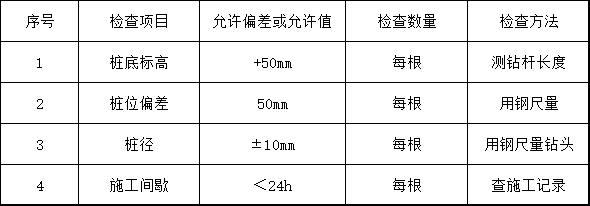

6,SMWThe quality inspection standard of construction pile shall conform to the following table.

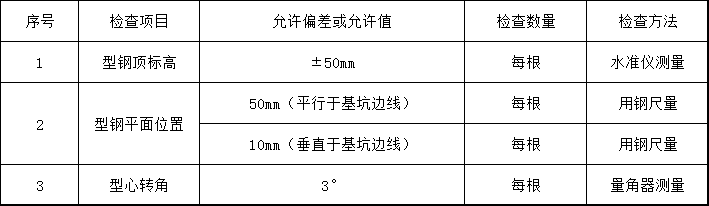

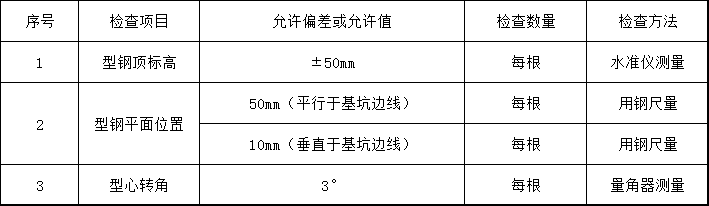

7,SMWThe allowable deviation of section steel insertion shall comply with the following table:

8,SMWThe number of sampling inspection of construction method steel cement soil mixing wall should not be less than the total number of piles5%.

Shanghai Qiangqiang Foundation Engineering Co., LTD. 's business covers foundation pit engineering, pile foundation engineering, land and waterFoundation treatment, slope treatment and other engineering fields. around "Excellent technology, reliable process, fast construction" technical requirements, is to provide customers with land, water foundation engineering technical consultation, construction services and other comprehensive solutions of the entity enterprise. Contact Number:400-1002850